1/2 air regulator: Unlocking the facility of precision airflow. This information delves into the specifics of this important element, exploring its numerous functions and making certain a radical understanding for each novices and consultants. From detailed specs and kinds to sensible set up and upkeep, we’ll cowl every little thing it’s essential know to make knowledgeable choices.

Understanding the nuances of 1/2 air regulators is essential for optimum efficiency in numerous functions. This information will offer you a deep dive into the world of those important instruments, overlaying every little thing from primary specs to superior troubleshooting. We’ll additionally discover the important thing variations between numerous manufacturers and their suitability for particular duties.

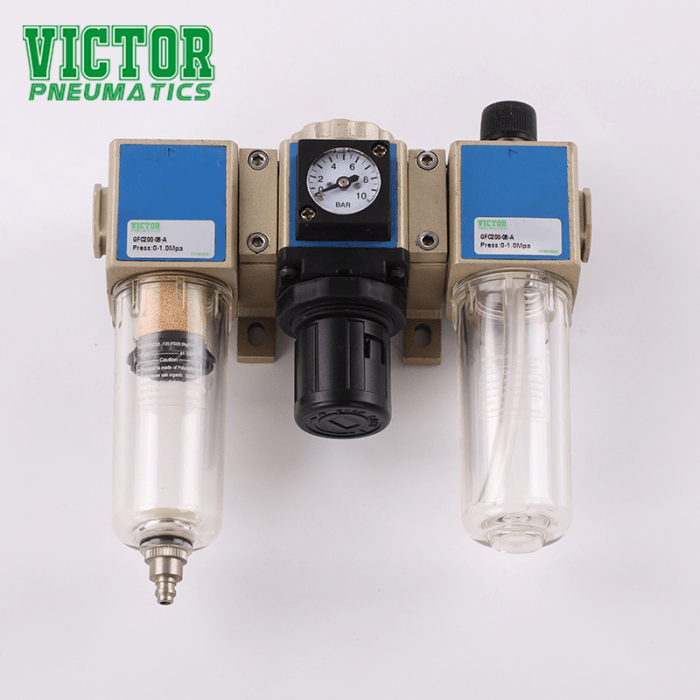

Product Specs

A 1/2 inch air regulator is a important element in lots of pneumatic techniques, exactly controlling the stress and movement of compressed air. Understanding its specs is important for choosing the proper regulator for a specific utility. This detailed overview gives insights into numerous points of 1/2 inch air regulators, from their building to their efficiency traits.This overview covers the important thing specs of 1/2 inch air regulators, enabling knowledgeable buying choices.

A 1/2 air regulator is essential for exact management of compressed air, particularly when coping with potential points like air in break traces. Understanding how one can successfully handle air in break traces, corresponding to these present in pneumatic techniques, is important for optimizing the efficiency and longevity of your 1/2 air regulator. Correct upkeep and troubleshooting of those techniques, together with using the proper 1/2 air regulator, ensures environment friendly operation.

air in break lines are a typical drawback requiring cautious consideration. A correctly functioning 1/2 air regulator performs a major position in stopping these points.

An intensive understanding of the different sorts, supplies, and security options is essential for optimum system efficiency and security.

Stress Vary and Circulate Price

The stress vary of a 1/2 inch air regulator dictates the utmost and minimal pressures it could management. Circulate price, typically measured in normal cubic toes per minute (SCFM), determines the quantity of air the regulator can deal with. These specs are instantly associated to the applying’s calls for. For instance, a regulator with a excessive movement price and large stress vary is right for high-volume air software operation.

Conversely, a regulator with a slender stress vary is likely to be appropriate for a exact utility like controlling a paint sprayer.

Varieties of 1/2 Air Regulators

Numerous forms of 1/2 inch air regulators exist, every with distinctive design options influencing efficiency. These embrace:

- Direct Appearing Regulators: These regulators use a easy diaphragm design, making them comparatively cheap and easy to keep up. They’re usually appropriate for functions with average stress and movement necessities.

- Pilot-Operated Regulators: These regulators make use of a smaller pilot stage to exactly management a bigger fundamental stage, leading to superior stress management and responsiveness. They’re typically most popular for functions demanding excessive precision, corresponding to within the manufacturing of intricate components.

- Twin-Stage Regulators: These regulators supply distinctive stress stability and fine-tuning functionality, typically exceeding the efficiency of direct-acting or pilot-operated varieties. They’re well-suited for functions requiring exact and constant stress, corresponding to in automated techniques.

Supplies and Development

The supplies utilized in setting up 1/2 inch air regulators considerably affect their efficiency and sturdiness.

- Physique Supplies: Frequent supplies embrace forged iron, aluminum, and brass. Forged iron provides sturdy sturdiness however could be heavier. Aluminum gives light-weight building, whereas brass provides corrosion resistance. The chosen materials is commonly a stability between price, sturdiness, and desired options.

- Diaphragms: These are usually created from rubber or artificial supplies. The precise materials alternative impacts the regulator’s resistance to chemical compounds and its lifespan.

Security Options

Security options are paramount in air regulators. These options shield tools and personnel from potential hazards.

- Over-pressure safety: This prevents injury from extreme stress, a important security measure.

- Stress reduction valves: These valves mechanically launch extra stress, stopping catastrophic failures.

- Seals and gaskets: Excessive-quality seals and gaskets guarantee leak-free operation and stop air loss.

Model Comparability Desk

| Model | Value | Options | Buyer Evaluations |

|---|---|---|---|

| AirPro | $150 | Sturdy building, responsive stress management | Constructive evaluations concerning sturdiness and efficiency |

| ProFlow | $200 | Superior pilot-operated design, exact stress regulation | Constructive suggestions on constant stress and responsiveness |

Purposes and Makes use of

A 1/2 air regulator is a important element in quite a few industrial and industrial settings. Its exact management over compressed air stress is important for environment friendly operation and security. Understanding its functions gives perception into the varied methods this gadget enhances productiveness and minimizes dangers. From easy pneumatic instruments to advanced manufacturing processes, the 1/2 air regulator performs an important position.

Frequent Purposes

The flexibility of a 1/2 air regulator stems from its potential to exactly handle compressed air stress. This exact management is important in numerous functions. This consists of controlling the power and pace of pneumatic instruments, sustaining constant stress for delicate tools, and stopping injury from over-pressurization. Understanding the particular necessities of every utility is vital to choosing the suitable regulator.

Industrial Purposes

A 1/2 air regulator is a basic element in a wide selection of industries. Its potential to supply constant and managed stress makes it an important a part of many manufacturing and industrial processes. For instance, within the automotive trade, exact air stress is required for portray, meeting, and different important operations. Within the building sector, pneumatic instruments are generally used, and a steady and dependable air provide is important for sustaining productiveness and effectivity.

Particular Capabilities

A 1/2 air regulator’s major operate is to scale back and regulate the stress of compressed air. This permits for the protected and managed use of air in numerous instruments and tools. In pneumatic instruments, the regulator adjusts the air stress to the optimum degree for every activity. This ensures constant efficiency and minimizes the chance of injury to the software or surrounding tools.

In automated techniques, a regulator maintains a steady and constant stress for the operation of equipment.

Comparability with Different Stress Management Gadgets

In comparison with different stress management gadgets, a 1/2 air regulator provides a stability of cost-effectiveness, effectivity, and ease of use. Whereas extra refined stress management techniques would possibly present extra advanced functionalities, the 1/2 regulator typically gives a enough answer for a lot of functions. For instance, in eventualities requiring exact stress management, a 1/2 regulator may not be the optimum alternative.

Optimizing your 1/2 air regulator efficiency is essential for constant operation. A important element impacting total system effectivity is the correct upkeep of your Peterbilt cab air bag. Peterbilt cab air bag situation instantly impacts the 1/2 air regulator’s potential to keep up optimum stress. Guaranteeing the system’s integrity is vital for the dependable operate of your 1/2 air regulator.

Nonetheless, its affordability and ease make it a preferred alternative for a lot of pneumatic functions.

Desk of Purposes and Necessities

This desk highlights the varied functions of a 1/2 air regulator, together with the important stress and movement price necessities, and particular regulator options.

| Software | Air Stress Necessities | Circulate Price Wants | Particular Regulator Options |

|---|---|---|---|

| Pneumatic Instruments (e.g., drills, affect wrenches) | 10-20 PSI | Variable | Adjustable stress, quick-release valve, security shutoff |

| Automated Meeting Traces | 5-15 PSI | Fixed, Excessive | Sturdy building, excessive movement capability, stress sensors |

| Printing and Packaging | 2-10 PSI | Average | Exact stress management, filters for contaminants |

| Welding and Slicing | 40-80 PSI | Variable | Excessive-pressure functionality, stress gauge, security reduction valve |

Set up and Upkeep: 1/2 Air Regulator

Correct set up and ongoing upkeep are essential for making certain the protected and environment friendly operation of a 1/2 air regulator. A well-maintained regulator will prolong its lifespan and stop potential hazards. This part particulars the mandatory steps and procedures for each set up and ongoing upkeep.Putting in a 1/2 air regulator requires cautious consideration to element and adherence to security protocols.

A 1/2 air regulator, essential for exact airflow management, can typically masks underlying points. In case your air air purifier is emitting an uncommon odor, it might level to a deeper drawback like a clogged filter or a malfunctioning half. Troubleshooting this typically includes investigating the supply, corresponding to inspecting the filter media and checking for correct set up. Understanding the potential causes, as detailed on this useful information on why does my air purifier smell , is vital to sustaining optimum air high quality and making certain your 1/2 air regulator features accurately.

Correct upkeep is important for environment friendly efficiency.

Failure to comply with these procedures might result in injury to the regulator, damage to personnel, or system malfunction. An intensive understanding of the steps concerned is paramount.

A 1/2 air regulator is essential for exact stress management, particularly when paired with a strong 12v on board air compressor, just like the one out there here. Correct stress regulation ensures constant efficiency and longevity for the complete system, in the end optimizing the effectiveness of the 1/2 air regulator itself.

Set up Process, 1/2 air regulator

Cautious set up is important to keep away from injury and make sure the regulator features as supposed. The next steps Artikel the proper process for putting in a 1/2 air regulator.

- Confirm the air provide stress aligns with the regulator’s specs. Mismatched stress can result in element injury or system failure.

- Make sure the regulator’s mounting floor is clear and free from particles. Contamination may cause leaks and different points.

- Place the regulator in line with the producer’s directions. Adherence to the diagram is important for optimum efficiency.

- Join the air provide tubing to the regulator’s inlet port. Utilizing the proper becoming sort is important to forestall leaks.

- Join the outlet tubing to the suitable system element. Correctly secured connections are important for security.

- Tighten all connections securely, following the producer’s torque specs. Over-tightening can injury parts.

- Take a look at the regulator for leaks. A leak detector is beneficial to make sure the system is safe.

- After leak checks, confirm the stress setting aligns with necessities. Changes could also be vital to make sure the specified stress.

Security Precautions

Implementing security precautions throughout set up is paramount to stopping accidents. These precautions assist decrease dangers related to high-pressure techniques.

- At all times disconnect the air provide earlier than beginning any set up or upkeep duties. It is a important security step.

- Put on applicable private protecting tools (PPE), together with security glasses and gloves. Defending your self from potential hazards is vital.

- Work in a well-ventilated space to attenuate publicity to potential contaminants. This reduces the chance of inhalation hazards.

- Make sure the regulator is correctly grounded to forestall electrical shocks.

- Comply with the producer’s security pointers all through the set up course of.

Upkeep Procedures

Common upkeep is important for optimum efficiency and longevity. A correctly maintained regulator will decrease points and prolong its lifespan.

A 1/2 air regulator is essential for exact stress management in numerous functions, particularly when working with vacuum and air compressor techniques. Understanding how these techniques work together, corresponding to with vacuum and air compressor setups, is important for optimizing efficiency and stopping injury. Correctly calibrated 1/2 air regulators are important for constant and protected operation.

- Examine all connections for leaks commonly. Leaks can point out points with the regulator or connections.

- Examine the regulator’s stress setting periodically to make sure it stays constant. Inconsistencies can point out an issue requiring consideration.

- Clear the regulator’s exterior and inside parts as per the producer’s suggestions. Common cleansing prevents mud accumulation.

- Lubricate transferring components as per the producer’s directions. Lubrication ensures clean operation and extends the regulator’s lifespan.

- Exchange worn or broken parts promptly. Broken parts can result in severe malfunctions.

Troubleshooting Frequent Points

Figuring out and addressing points rapidly can stop extra important issues. This desk particulars widespread points and their options.

| Drawback | Answer |

|---|---|

| Irregular stress readings | Confirm connections, test for leaks, and recalibrate the regulator. |

| Excessive stress readings | Guarantee appropriate stress settings and test for any blockage within the air traces. |

| Low stress readings | Confirm connections, test for leaks, and modify the regulator’s settings. |

| Noisy operation | Examine for any obstructions and guarantee correct lubrication. |

Advisable Instruments

An inventory of important instruments for set up and upkeep is supplied.

| Software | Description | Function |

|---|---|---|

| Adjustable wrench | For tightening and loosening nuts and bolts | Important for set up |

| Torque wrench | For exact tightening of connections | Vital for stopping injury |

| Leak detector | For figuring out leaks within the system | Ensures system integrity |

| Screwdriver set | For disassembling and reassembling parts | Essential for upkeep duties |

Closing Wrap-Up

In conclusion, the 1/2 air regulator, a seemingly easy gadget, performs a major position in numerous industrial and sensible functions. This information has outfitted you with the data to know its options, makes use of, and upkeep, in the end serving to you select the proper regulator on your particular wants. Bear in mind, correct set up and upkeep are key to making sure long-lasting efficiency and security.

High FAQs

What are the everyday stress ranges for 1/2 air regulators utilized in pneumatic instruments?

1/2 air regulators utilized in pneumatic instruments usually function inside a stress vary of 10-20 PSI, providing adjustable stress to accommodate the particular wants of varied instruments.

How do I select the proper 1/2 air regulator for my utility?

Deciding on the proper 1/2 air regulator includes contemplating elements corresponding to the specified stress vary, movement price, and mounting choices. Consult with the specs and utility tables inside this information to make an knowledgeable choice.

What are some widespread troubleshooting steps for a malfunctioning 1/2 air regulator?

Frequent troubleshooting steps for a malfunctioning 1/2 air regulator embrace checking for leaks, making certain correct connections, and verifying the regulator’s stress settings. The information gives a complete troubleshooting desk to assist you.

What are the security precautions when working with 1/2 air regulators?

Security precautions when working with 1/2 air regulators embrace sporting applicable private protecting tools (PPE), following set up pointers meticulously, and making certain correct air flow within the work space. At all times prioritize security.